Introduction

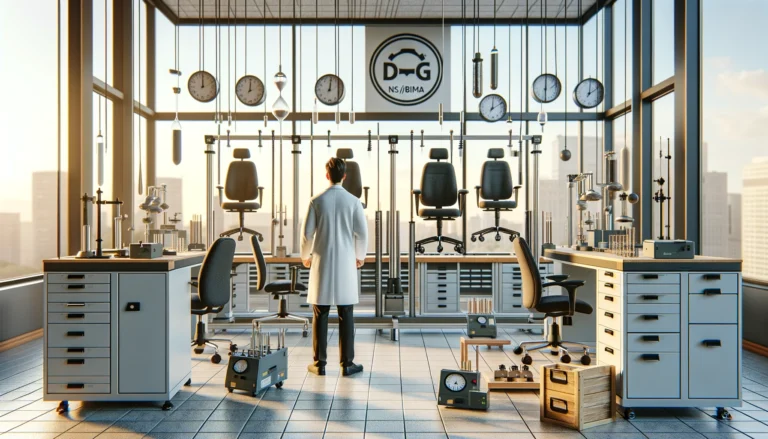

At CDG Inspection PVT LTD, we are proud to be a leading provider of inspection services that ensure quality and compliance across various industries. One of the key aspects of our services is ANSI/BIFMA X5.5 testing. In this comprehensive guide, we will explore the intricacies of ANSI/BIFMA X5.5 testing, specifically in the context of Brunei.

What is ANSI/BIFMA X5.5 Testing?

ANSI/BIFMA X5.5 is a set of guidelines established by the American National Standards Institute (ANSI) and the Business and Institutional Furniture Manufacturers Association (BIFMA). It focuses on evaluating the performance and durability of office furniture, such as chairs and desks, to ensure they meet industry standards for safety, ergonomics, and structural integrity.

The Importance of ANSI/BIFMA X5.5 Testing

In Brunei, as well as in many other countries, there is a growing demand for high-quality office furniture. With an increasing emphasis on workplace ergonomics and safety, both businesses and consumers want assurance that the furniture they purchase adheres to rigorous standards. This is where ANSI/BIFMA X5.5 testing plays a crucial role.

Ensuring Compliance with Regulatory Requirements

Compliance with regulatory requirements is essential for manufacturers and importers of office furniture in Brunei. ANSI/BIFMA X5.5 testing provides a standardized method for assessing whether furniture products meet the necessary criteria for performance, safety, and durability. By undergoing this testing process, manufacturers can demonstrate their dedication to quality and regulatory compliance.

The Testing Process

The ANSI/BIFMA X5.5 testing process involves subjecting furniture products to a series of rigorous tests to evaluate their performance under various conditions. These tests may include:

Seating Endurance Test: Evaluating the structural integrity and longevity of chairs through repeated stress cycles.

Drop Impact Test: Assessing the resistance of furniture components to impact by subjecting them to controlled drops.

Leg Stability Test: Evaluating the stability and strength of chair legs to ensure they can bear the intended weight.

Backrest Resilience Test: Examining the resilience and durability of chair backrests through repeated bending.

Advantages of ANSI/BIFMA X5.5 Testing for Enterprises

For companies operating in Brunei’s furniture sector, investing in ANSI/BIFMA X5.5 testing provides numerous advantages:

Improved Product Quality: By following strict testing standards, companies can guarantee that their furniture items meet the highest quality standards, enhancing customer satisfaction and brand reputation.

Market Entry: Adhering to ANSI/BIFMA X5.5 standards allows access to both local and international markets, showcasing a dedication to quality and safety that resonates with consumers and regulatory bodies.

Risk Management: Proactively testing products for compliance helps companies reduce the risk of recalls, liability issues, and regulatory fines, safeguarding their finances and reputation.

Competitive Edge: In a competitive market, certification to ANSI/BIFMA X5.5 standards can be a key differentiator, helping companies differentiate themselves from competitors and attract discerning customers.

Collaborating with CDG Inspection PVT LTD

At CDG Inspection PVT LTD, we recognize the significance of compliance and quality assurance in the furniture industry. With our expertise in ANSI/BIFMA X5.5 testing and dedication to excellence, we assist Brunei-based businesses in navigating regulatory compliance confidently.

From comprehensive testing services to customized consultancy, we provide a range of solutions tailored to meet our clients’ specific requirements. Our cutting-edge facilities, skilled technicians, and customer-centric approach ensure a seamless experience.

Conclusion

In conclusion, ANSI/BIFMA X5.5 testing plays an important role in ensuring the quality, safety and durability of office furniture in Brunei. By partnering with a trusted inspection company like CDG Inspection PVT LTD, companies can streamline their compliance efforts, improve product quality and gain a competitive edge in the marketplace